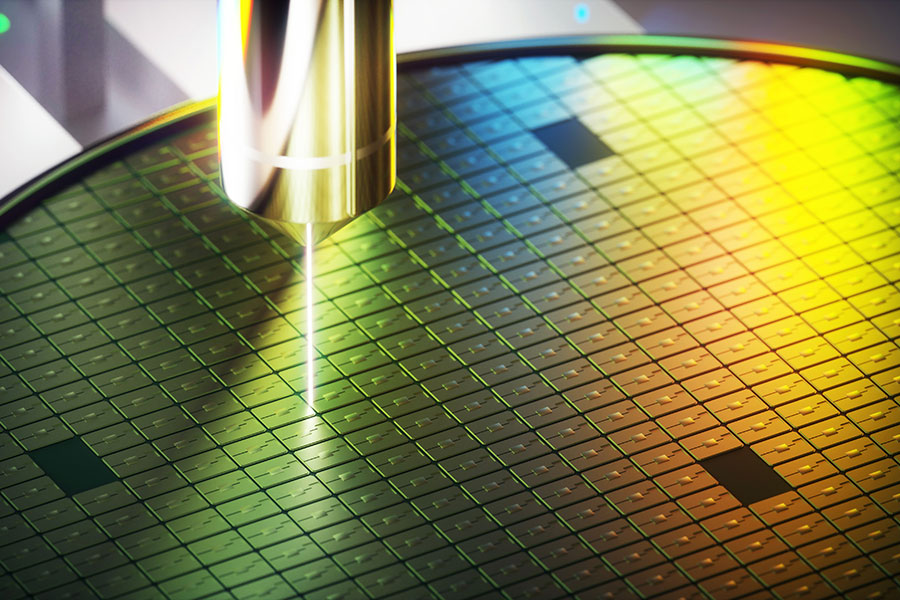

DB Hitek, a South Korean wafer foundry, will produce a chip for Tesla cars. This car chip is designed by an American fabless chip company, which will conduct audits of DB Hitek in June and October. The audit in June will be conducted separately by this fabless factory, and Tesla will also participate in it in October.

According to sources, after the audit, this South Korean foundry is expected to use its bipolar CMOD-DMOS (or BCDMOS) process to manufacture chips.

This process combines simulation, logic devices, and high-voltage devices into one chip, thereby reducing chip size, production time, and cost. This process is mainly used for manufacturing power management ICs.

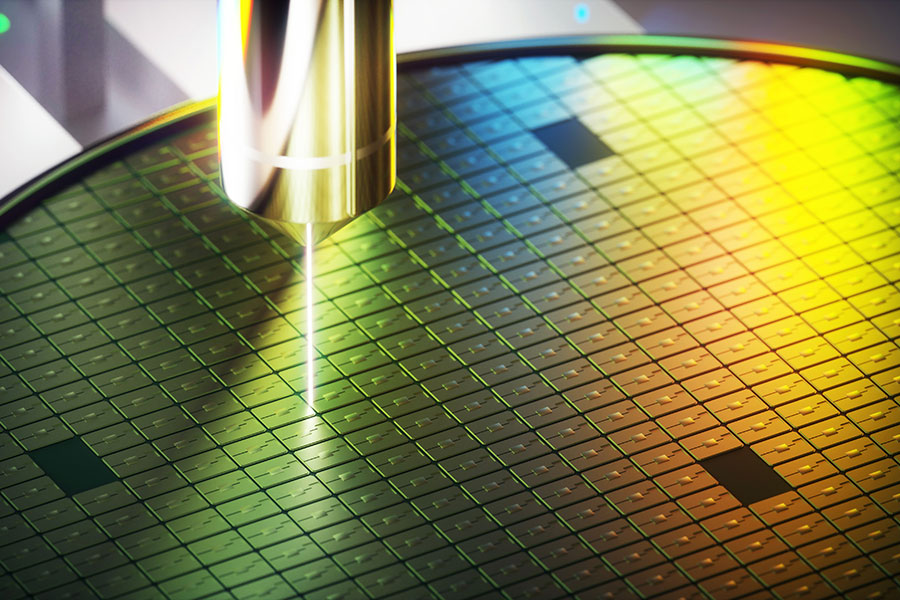

Tesla currently uses various fabless and foundry chip companies to manufacture its semiconductors. It designs its own advanced driving assistance system and SoC, and hands over the production workload to Samsung's OEM factory.

For commercial chips such as power management ICs and silicon carbide (SiC), Tesla hands over the design workload to other fabless companies.

SK Keyfoundry in South Korea is also manufacturing power management ICs for Tesla, with plans to start production in July.

According to sources, DB Hitek operates an 8-inch contract factory with a current operating rate of approximately 75%. They also stated that the operating rate of Samsung and SK Keyfoundation's 8-inch foundries is below 70%.