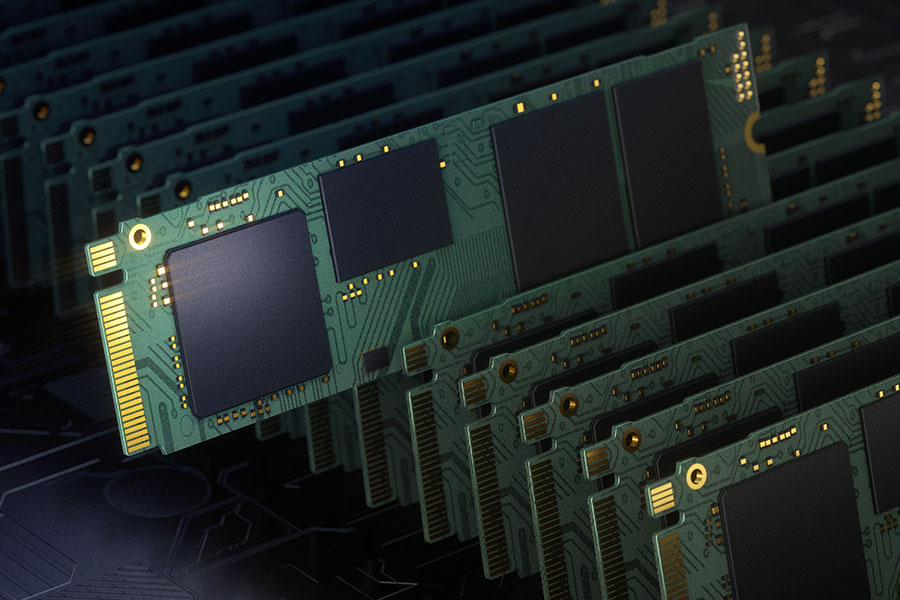

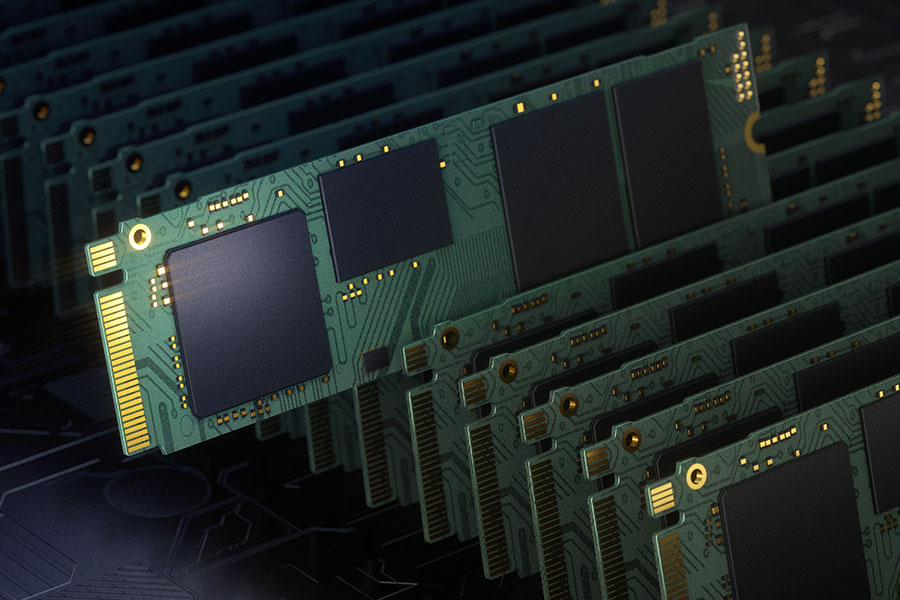

According to reports, Samsung has reduced the use of thick photoresist (PR) in its latest 3D NAND lithography process, resulting in significant cost savings. However, this move may affect its Korean supplier Dongjin Semiconductor.

Samsung has reduced the PR usage for 3D NAND production by half, reducing the consumption from 7-8 cc per coating to 4-4.5 cc. Industry analysts predict that Dongjin Semiconductor's revenue may decline, highlighting the broader impact of cost cutting measures on supply chain dynamics.

It is reported that Samsung is committed to improving NAND process efficiency and reducing costs, and has successfully reduced the use of photoresist through two key innovations. Firstly, Samsung optimized the revolutions per minute (rpm) and coating machine speed during the application process, reducing the use of PR while maintaining optimal etching conditions, and significantly saving costs while maintaining coating quality. Secondly, the etching process after PR application has been improved, and although the material usage has been reduced, equivalent or better results can still be obtained.

The increase in stacking layers in 3D NAND has pushed up production costs. In order to improve efficiency, Samsung has adopted KrF PR in its 7th and 8th generation NAND, enabling the formation of multiple layers in a single application. Although KrF PR is highly suitable for stacking processes, its high viscosity poses challenges to coating uniformity and increases production complexity. PR production involves complex processes, high purity standards, extensive research and development, and long validation cycles, setting huge technical barriers for new entrants to the market.